SKL is reader supported. When you buy through links on our site, we may earn affiliate commission. Learn more here.

A good pair of jeans is a closet staple we can all appreciate. While denim is a popular classic for many, there are some lesser-known downsides to your favorite pair of jeans.

Just as with all clothing, so much goes into the creation of denim pieces. And not all of it is as feel-good as finding that perfect fitting jean.

Today’s blog will explore how denim is made and its impact on people and the planet. We will also highlight a brand that is working to improve denim creation and is paving a better way forward for all.

All About Denim

The value of the global denim market sits at around $65 billion with 3 billion pairs of jeans on the market currently.

Denim is a staple in both the global textile market and in our closets. Known for its versatility and durability, denim started in France, made its way to America as workwear for miners, and then became a favorite everyday style after being popularized by stars like James Dean and Marlon Brando.

How Denim is Made

Denim is traditionally created from a cotton twill weave. In fact, around 12% of cotton is used to make denim garments. The twill weave has a subtle diagonal pattern and is known for its durability.

To make denim, the raw cotton is spun into a yarn that is typically treated and dyed before being woven into a fabric. The quality and traits of the yarn (such as twist, size, strength, and softness) are vital to how the yarn will interact with the dyes and what the denim will ultimately look and feel like when woven.

To achieve the classic blue, indigo dye is the common choice. Indigo doesn’t dye cotton well, so chemical processes and additional steps must be applied to help the color stay. Synthetic indigo is used almost exclusively over natural indigo and is used with a ring-dyed effect (leaving the core of the yarn white) to achieve the naturally worn look of denim.

After the yarn has been dyed, it is turned into a fabric via a warp and weft method. The warp is the long vertical blue yarns that the white weft yarns are threaded through on a shuttle or projectile loom. The woven fabric then goes through finishing processes and treatments to create the final desired look.

Along each step of the way, there are a variety of different approaches that a producer may opt for, making denim production just as varied as how we style it.

One common variant is stretch denim. Stretch denim is made by incorporating spandex, elastane, or polyester into the fabric to make the material softer or more form-fitting.

With all of the steps and possible variations in denim production, every decision has the potential to make the process more or less sustainable.

Let’s explore some of the main concerns about denim’s environmental impact.

This post is all about the denim industry and the sustainability of MUD Jeans.

The Sustainability Of Denim

One might assume that denim is a relatively sustainable material. After all, it is likely to be made out of natural fiber cotton.

While we are fans of cotton here at Sustainably Kind Living, there’s a lot more material that goes into making denim before we can classify it as sustainable.

We must look at raw materials, production processes, worker safety, quality and usage, and end-of-life potential.

Raw Material

Not all cotton is created equal. While cotton has a reputation for being a “thirsty” and pesticide-heavy crop, this isn’t necessarily true, especially when comparing it to other agricultural products. It all depends on where it is being grown, what pesticides are being used and why, and what practices the farmers are using.

Organic cotton farming can ensure these things are managed well, yet organic cotton only makes up a tiny part of the cotton market (1.4%). While cotton is a preferred material sustainably, just how sustainable depends on a lot of factors that can’t be generalized.

Additionally, with most denim incorporating stretch now, fossil-fuel-based synthetics are being used with cotton in jeans. Stretch denim generally has a shorter lifespan due to lower quality and poses recycling problems.

Production Processes

This is the stage when a lot of red flags pop up for denim and its sustainability. As individuals and consumers, we are often unaware of the many components that go into making the clothes we wear.

Unfortunately, crafting our jeans can involve a lot of toxic chemicals and harmful treatments. These processes can damage the workers’ health, the community surrounding factories, our environment, and ultimately the final wearers of the garments.

The Toxicity of Denim

Fashion production can be a chemically-intensive process. And some of those chemicals are hazardous. Among the harmful components of dyes and chemical treatments are carcinogens, hormone disruptors, and heavy metals.

Indigo dye is the go-to choice to achieve denim’s classic blue color. As indigo pigment is inherently insoluble in water, it requires chemical and process intervention to help the color stick to the yarn.

Sodium hydrosulphite, caustic soda, aniline, formaldehyde, hydrogen cyanide, and sodium amide (which can explode if it comes in contact with oxygen in the air or water) are all chemicals involved in the dyeing process.

Additionally, because dyes can’t be 100% fixed, inevitably, unfixed dyes are released into waterways. While chemicals aren’t inherently bad, it is vital that they are used responsibly and handled safely. The problems come when they aren’t.

These chemicals don’t just impact the factory and the people in it. The effects of toxic chemicals and poorly managed wastewater can wreak havoc on the communities that support fashion production, as is detailed in the documentary RiverBlue.

In Dhaka, Bangladesh, the water is so toxic because of pollution from the fashion factories that the rivers cannot sustain life, and the community cannot use it.

Similarly, in India surrounding the Ganges River, polluted water from tanneries ends up being used to irrigate land and those polluting chemicals can be found in the food.

Xintang, China, known as the denim capital of the world, which produces a large amount of China’s jeans and its exported jeans, has faced putrid-smelling, blue-dyed rivers from denim factories along with heavy metals found in the surrounding environment from the untreated wastewaters.

Worker Safety

With the use of so many toxic materials across the supply chain, this no doubt puts workers in harm’s way. This begins at the cotton farm with insecticide poisoning. Cotton’s relationship with pesticides is often shrouded in misused information that vilifies it.

Ultimately, cotton accounts for 4.8% of all global pesticide sales (not the 25% of insecticide use that typically gets associated with it). Around 44% of farmers are poisoned by pesticides every year (this is not exclusive to cotton farming).

Pesticide Action Network’s research across three cotton-producing countries shows that 12% of cotton workers report severe or permanent health damage related to their work. It’s very important that we are critical of how pesticides are being used because they can lead to acute and chronic health conditions for farm workers.

One of the most endangering aspects of denim production comes from the chemicals and practices used in the factories and dye houses. The heavy metals found in the dying process are toxic and affect multiple bodily organs and systems, with damage ranging from skin conditions to birth defects to cancer.

The finishing processes that go into creating the final looks of denim also pose problems. For example, sandblasting, which creates a distressed look, produces fine dust that gets inhaled by the workers and leads to lung diseases like silicosis. To achieve a faded, bleached, or acid wash, potassium permanganate or hypochlorite is used which creates dangerous fumes leading to lung problems and skin issues.

Garment work can be dangerous and hard on the body, especially when producers and brands are not doing their due diligence to protect workers.

Levi’s, one of the most popular denim brands, has been facing criticism for not participating in worker protections like the Bangladesh and Pakistan Accord. This is heightened by the fact that 4 garment workers died in a factory producing for Levi’s due to inhaling toxic fumes. It’s absolutely unacceptable that lives are being risked and harmed for the sake of fashion.

Denim End of Life

Not only does denim pose threats to our environment and the people who make it, but the problems continue down the line up until the end of denim’s life.

With most modern denim styles incorporating synthetic materials to make it stretch, denim becomes harder to recycle. We currently don’t have the recycling infrastructure to recycle blended textiles at scale.

Plus, how the material is chemically treated impacts its recyclability, and because there are no requirements for reporting or labeling those processes, it’s almost impossible to separate the contaminated components with the existing sorting technology.

This means most textile “recycling” is more likely a downcycling process. It’s common to see denim take-back programs that shred the material into insulation.

Additionally, jeans’ metal components and labels create another recycling barrier because the garments have to be deconstructed with the metal removed before they can go through any machinery in some sort of recycling or downcycling process. This currently can’t be automated as removing the small metal details takes special attention.

To make denim’s end-of-life more sustainable, recyclability must be considered in the design process. This means mono materials, non-toxic treatment, and ease of disassembly are factors designers and brands should be prioritizing in making denim more circular.

There’s certainly much about denim production that is harmful and needs reform. Many sustainable alternatives exist, but it’s a matter of urging brands and producers to opt for better options and making them more scalable and cost-effective.

When it comes to pushing the denim industry forward, there’s one brand that’s truly leading the way in sustainable denim production.

How MUD Jeans is Making Sustainable Denim

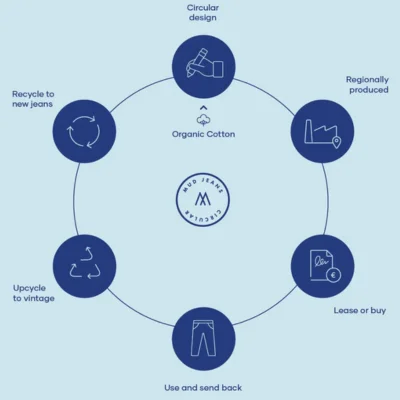

MUD Jeans is pioneering circular denim. This Netherlands-based denim brand is showing consumers and the fashion industry how sustainable jeans can be made. As a B-Corp, MUD is working on end-to-end circularity with sustainable materials and responsible practices.

They are innovating with their materials and giving customers the opportunity to lease their jeans for a low monthly fee.

Here’s what makes MUD Jeans different:

Recycled and Recyclable Jeans

MUD is prioritizing and pioneering the use of recycled cotton. Currently, MUD jeans are made of a mix of OCS-certified organic cotton and GRS-certified post-consumer recycled cotton.

Many brands that use recycled materials are using pre-consumer recycled materials which means they’re using factory waste and off-cuts. Post-consumer recycled materials come from garments that the individual has discarded after use.

By using post-consumer recycled cotton, MUD is capturing an often ignored part of the fashion waste stream. While MUD has the highest recycled jeans makeup using 40% post-consumer recycled material, they are working on raising that number to 100% to create fully recycled jeans.

This project, known as the Road to 100, involves collaborating with a university and incorporating both chemical and mechanical recycling. They’ve achieved creating a 100% fully recycled sample and are applying their learnings to new projects and working to gradually scale up to 100% recycled content in their denim offerings.

MUD also has a denim take-back recycling program which feeds into their recycled content, making it truly circular. In contrast, many brands with recycling programs simply send the garments they receive to their recycling partners to manage, and the received garments aren’t necessarily used in their own supply chain. But MUD is using the jeans they receive from customers to make their new jeans in partnership with their recycling collaborators.

Additionally, MUD uses 100% stainless steel for their buttons and rivets, printed labels instead of leather to maintain the mono-material of the denim, and recycled elastane or LYCRA® T400® EcoMade for a sustainable stretch (while still keeping the synthetic material at less than 4% to maintain recyclability).

Sustainable & Transparent Processes

In addition to material innovation, MUD is applying more sustainable processes across their supply chain. First, they have direct relationships with a limited supplier list so they know exactly how their jeans are being made and can ensure responsible production.

In terms of addressing the harmful processes that can go into denim production, MUD has eliminated the use of PP spray (potassium permanganate), uses Cradle2Cradle indigo dye, and are employing water and energy-saving practices. Instead of toxic bleaching or stone washing, they use innovative techniques like laser, ozone, and “eco-stones” to achieve the desired finished look.

When it comes to transparency and traceability, MUD lists out their exact suppliers and shares their Life Cycle Analysis publicly. Beyond their own improvement, MUD also works to support other industry players and educate professionals and students alike on better, sustainable practices.

MUD isn’t just doing this for their own success. They truly want to drive change in the fashion industry, eliminate waste, and pioneer a circular way of doing business, all while making great jeans!

When it comes to sustainable fashion brands, MUD Jeans is truly putting in the work. They are an excellent example of a brand that is doing right by the people who make their clothes, respecting the planet, and offering great value to their customers without greenwashing.

This post was all about the denim industry and the sustainability of MUD Jeans.

This has been your comprehensive guide to denim and its environmental impact. While much about denim production needs to change, we are glad to share about a brand that is making a true difference! If you’re looking for your next favorite sustainable denim brand, MUD Jeans is a great option!

If you enjoyed this article on the Denim Industry, check out these other articles below!

- Organic Cotton Fabric Guide: What Is Organic Cotton, How Is It Made & Is It Sustainable?

- The 21 Best Sustainable Jeans Brands Of 2024, Reviewed!

- The Top 25 Ethical Fashion & Textile Certifications You Need To Know

+ show Comments

- Hide Comments

add a comment